Description

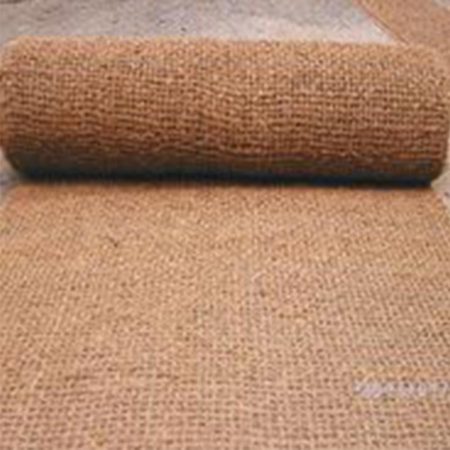

Coir are generally obtained from husking the fully matured coconuts from hard shell by a De-Husking Machine which crushes the whole fruit to give a loose fiber (average of 2000 coconuts per hour). The fibrous husks are then soaked in stagnant water (about 10months) to swell the fibers and make them soft called Retting.

The coir fiber is the thickest and most resistant of all commercial natural fibers and have a higher elongation ability. They entrap surrounding air, giving rise to resilience to the fiber, and increases the time water takes to penetrate the fibers. Their low decomposition rate is the key advantage for making durable products. These properties of coir are less affected by wet or damp conditions. The thickness of coir fiber limits the products made by coir being coarser and heavier.

In addition, these fibers can be much more stretched beyond their elastic limit, around 5-10 times of their weight. Coir fiber is a good low cost adsorbent substitute.

- The coir fiber is by-nature a waterproof material and is a 100% organic, renewable product that’s untreated & completely safe for animals and the environment.

- Providing amazing benefits, fiber’s interlocking ability makes sure deep absorption.

- It practically eliminates odor and thereafter flies and pests as well.

- A unique aspect of coconut coir is its ability to insulate, providing thermal control during cold winters or blazing summer heat.

- And it makes an excellent soil amendment, so can recycled safely into your garden, eliminating waste and doing wonders for your plants.